Case Studies

We help big projects become a reality.

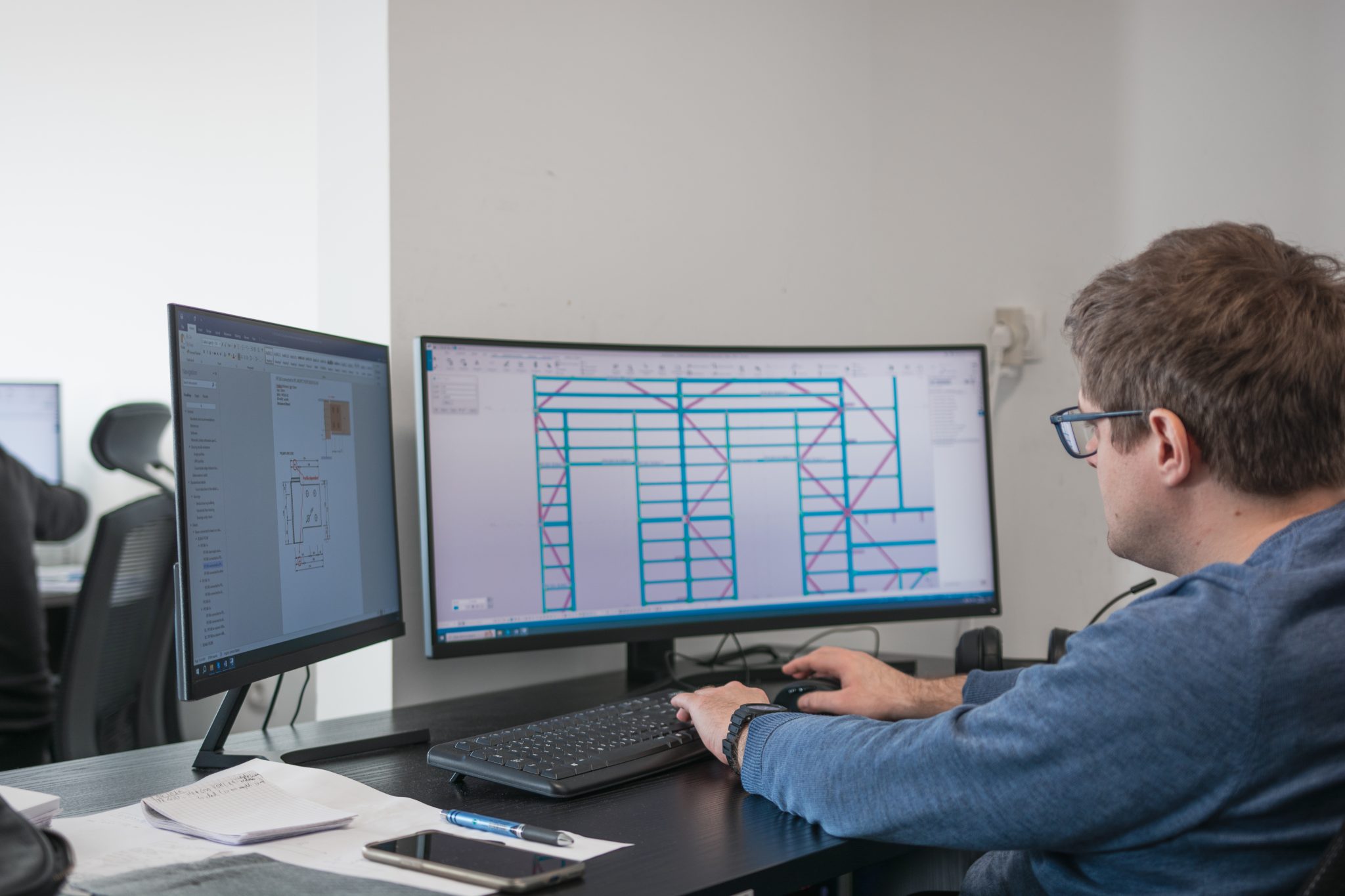

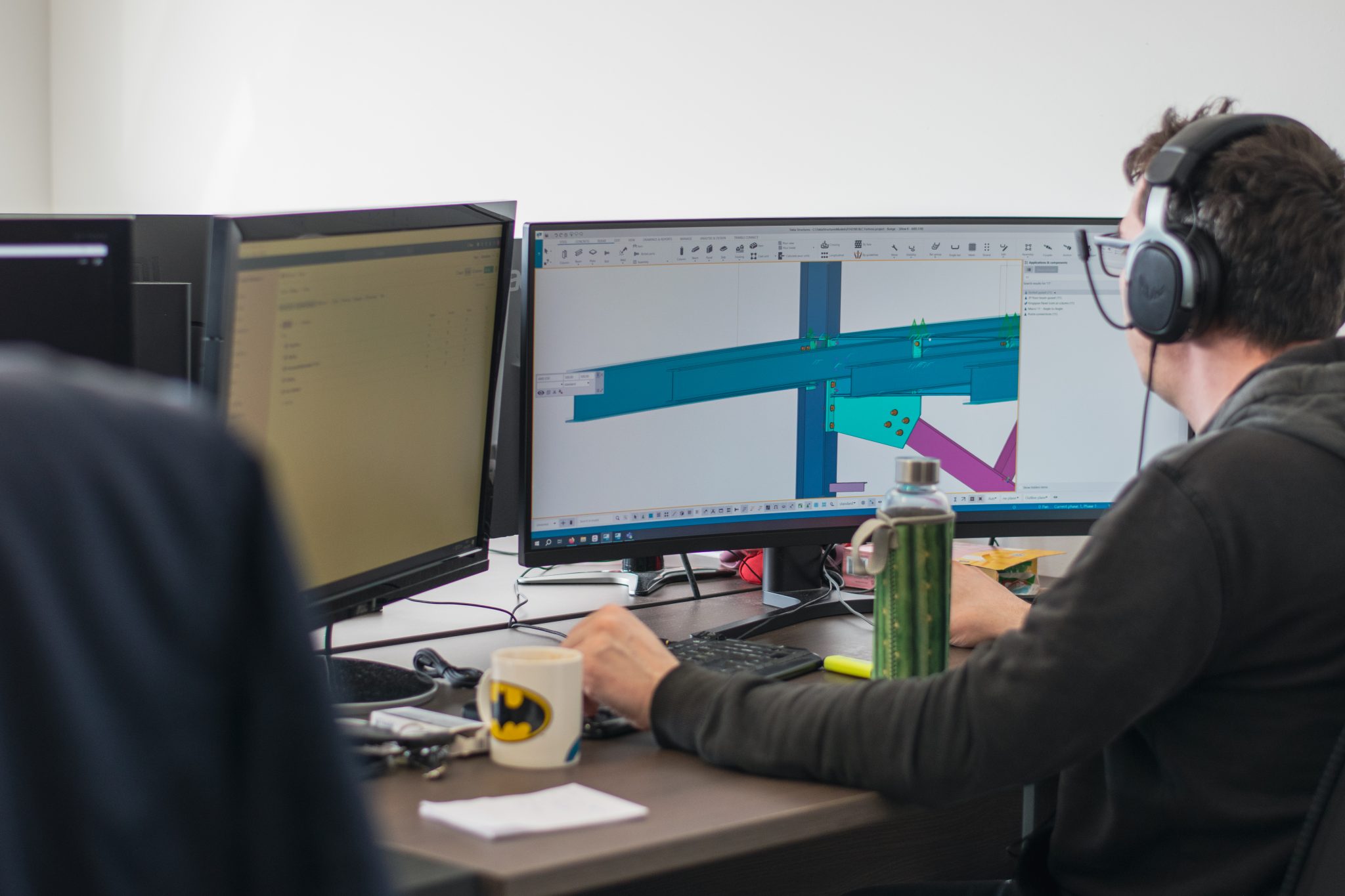

We provide our customers with unbeatable design and engineering services – from 3D modeling to technical drawing suited to the manufacturing process.

We provide our customers with unbeatable design and engineering services – from 3D modeling to technical drawing suited to the manufacturing process.

Our extensive portfolio of successfully completed projects and contented clients serves as the driving force behind our team. It fuels our motivation and determination to continue growing and shaping the future.

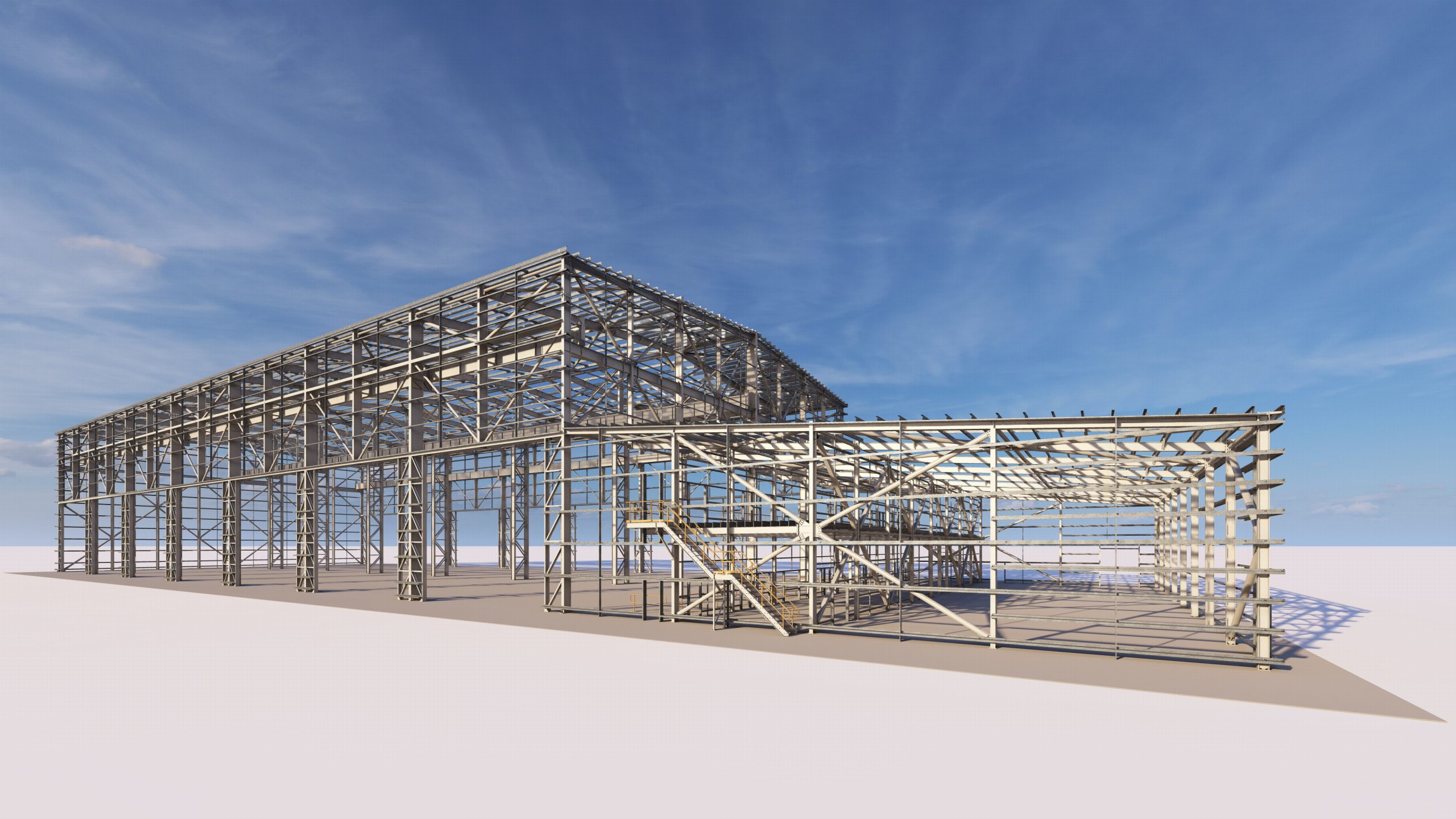

The initial project began with structural design provided as input. As per our usual scope of work, we refined the design, made the 3D model and created the fabrication drawings. What was challenging about this project was that structural project was partially undefined and requesting missing connections could’ve prolonged the project. Therefore it was our task to design the missing connections and create the fabrication model, which was done on time.

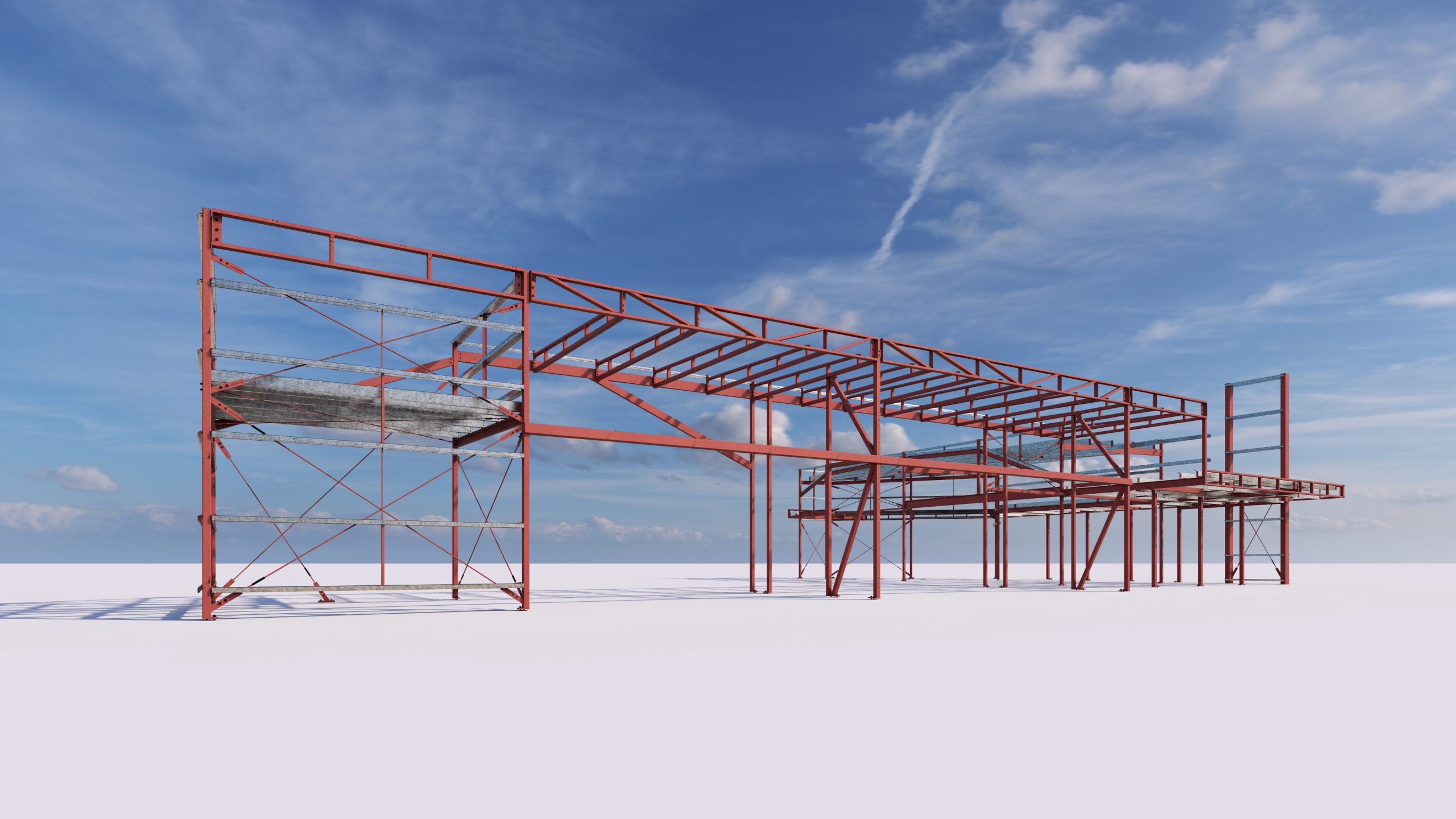

Completing this project presented its fair share of challenges - primarily due to demanding time constraints and the fact that the design wasn't fully finalized before we commenced steel detailing. We managed to work through all the difficulties and that resulted with great feedback from the builder - “Every bolt was done on point.” That reaffirmed us, and gave us a boost for future projects to deliver high-quality results even under challenging circumstances.

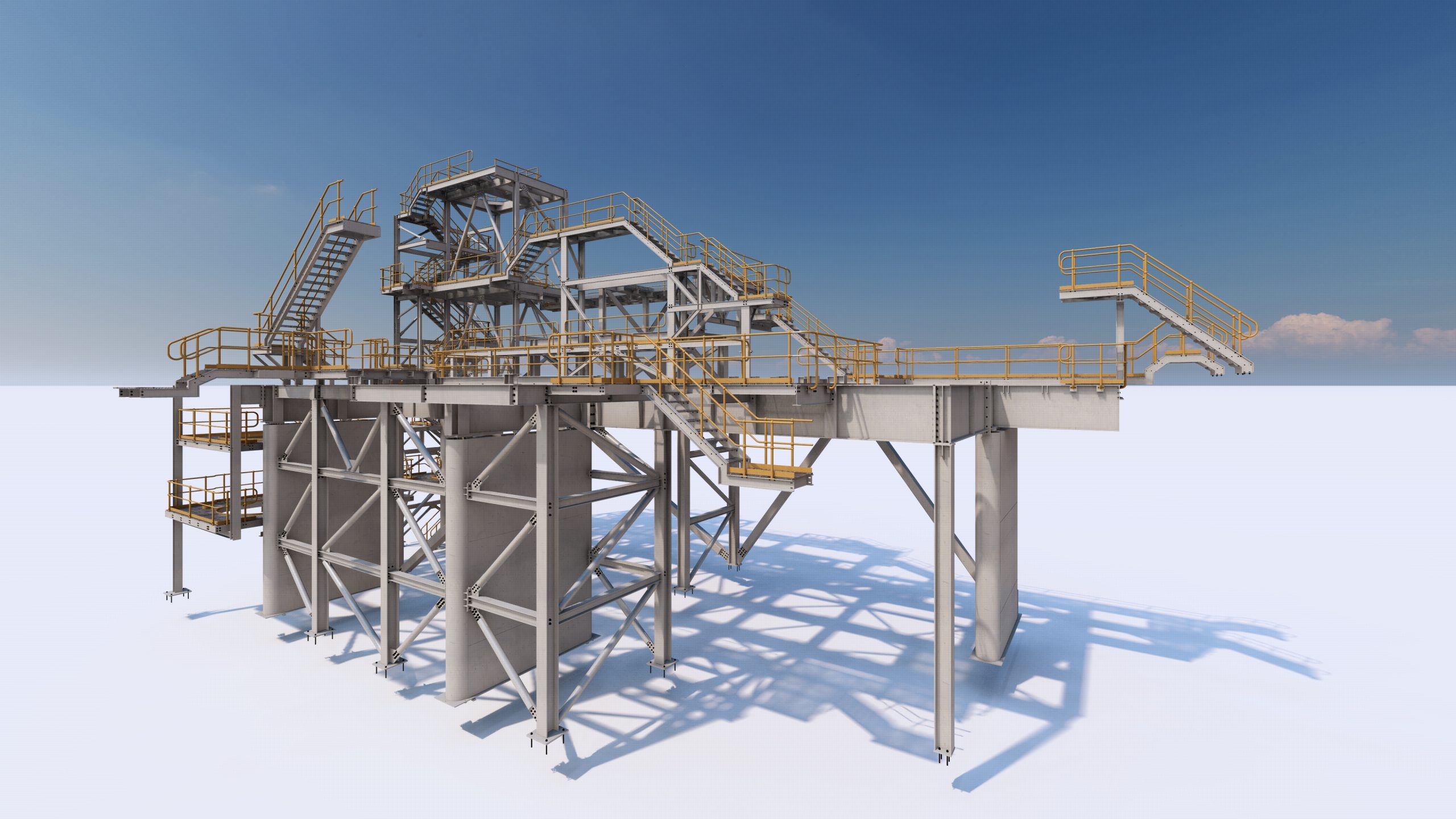

Our team got to work on two water reservoirs with accompanying auxiliary structures, stair tower and bridges. The project was divided in sub models, and issued as such - each reservoir, stair tower structure, and bridges structure. Utilizing similarities between reservoirs increased efficiency, as the first reservoirs model was used as a base for the second reservoirs model. All models were combined and overlapped with provided on site concrete survey.

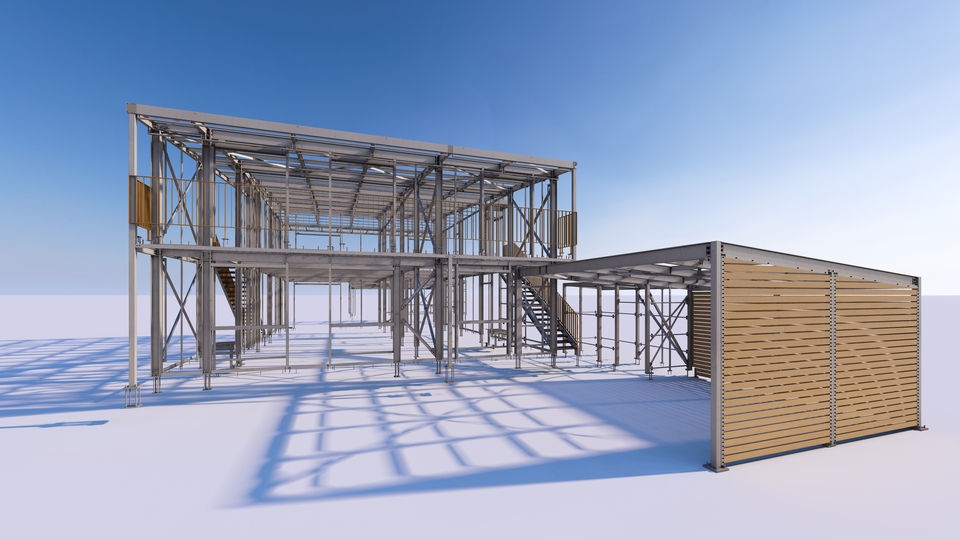

Even though the project began with a basic layout provided by the client, our team approached it with the same level of dedication and energy that we bring to every job. We embraced the challenge of performing calculations, creating detailed models, and preparing the fabrication package. While the project itself may have seemed relatively straightforward, our commitment to excellence and our great work ethic ensured that we delivered outstanding results.

The project specifications called for an impressive 2.5 meters of wet snow per square meter, and in response, the architect and client opted for a 3-degree slope design. Once we completed the calculations and engaged in 3D modeling and detailing, we found that our collaboration with both our engineer and fabricator played a pivotal role.

Our website uses cookies to improve your browsing experience and customize content according to your preferences.

We place a significant emphasis on your privacy and ensuring you have a great experience. We collect data about how you use this website to help us customize information and develop applications that you will like. Your Data Privacy Matters: Can We Collect and Utilize Your Information? Learn more about who we are, how you can contact us, and how we process personal data in our Privacy Policy. Your consent applies to the following domain: www.cadeli.hr