When it comes to complex infrastructure, precision engineering and solid structural design are key to long-term performance. The Harrington Park Water Pumping Station, located in the Macarthur Region of Sydney, stands as a perfect example of how detailed planning, advanced modelling, and high-quality steelwork come together to deliver reliability and strength.

Project Overview

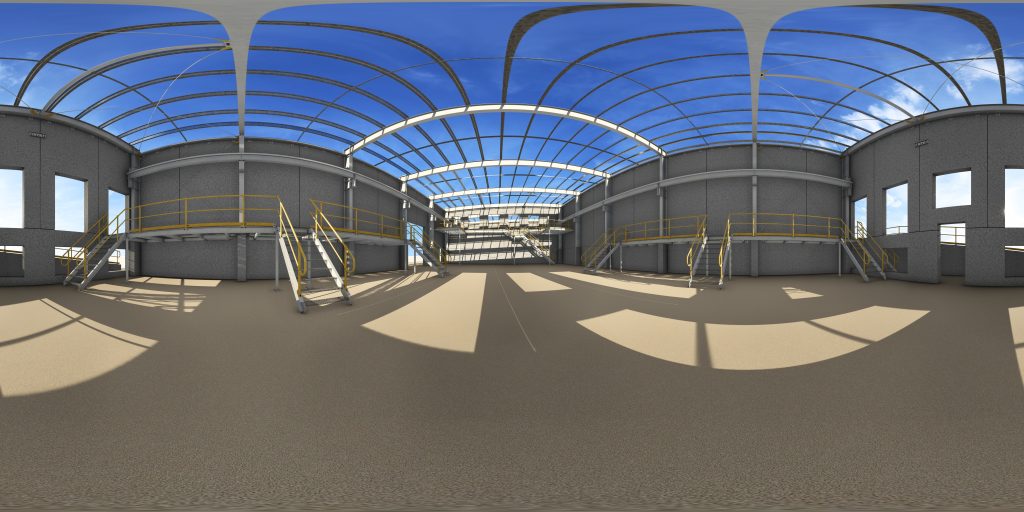

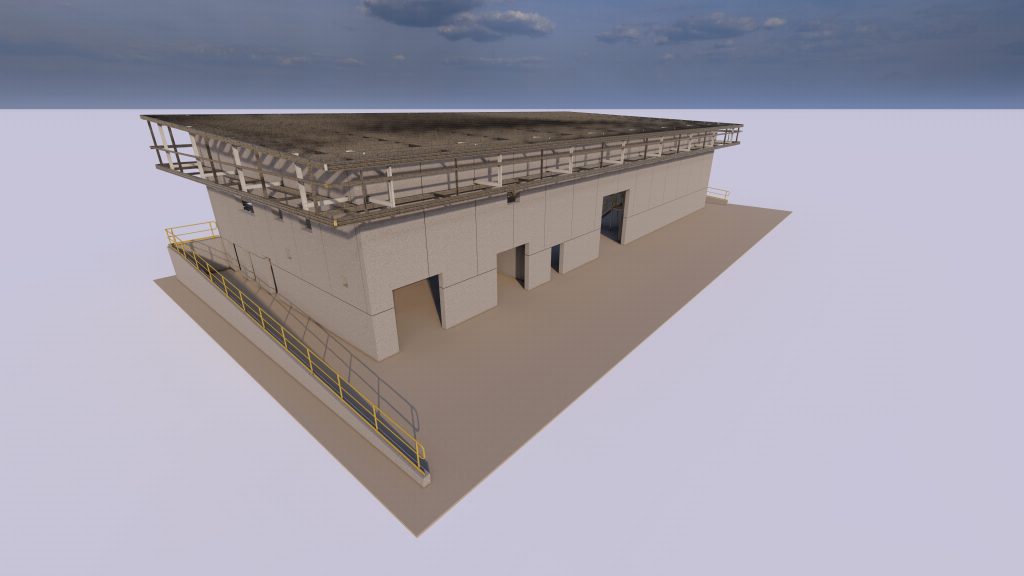

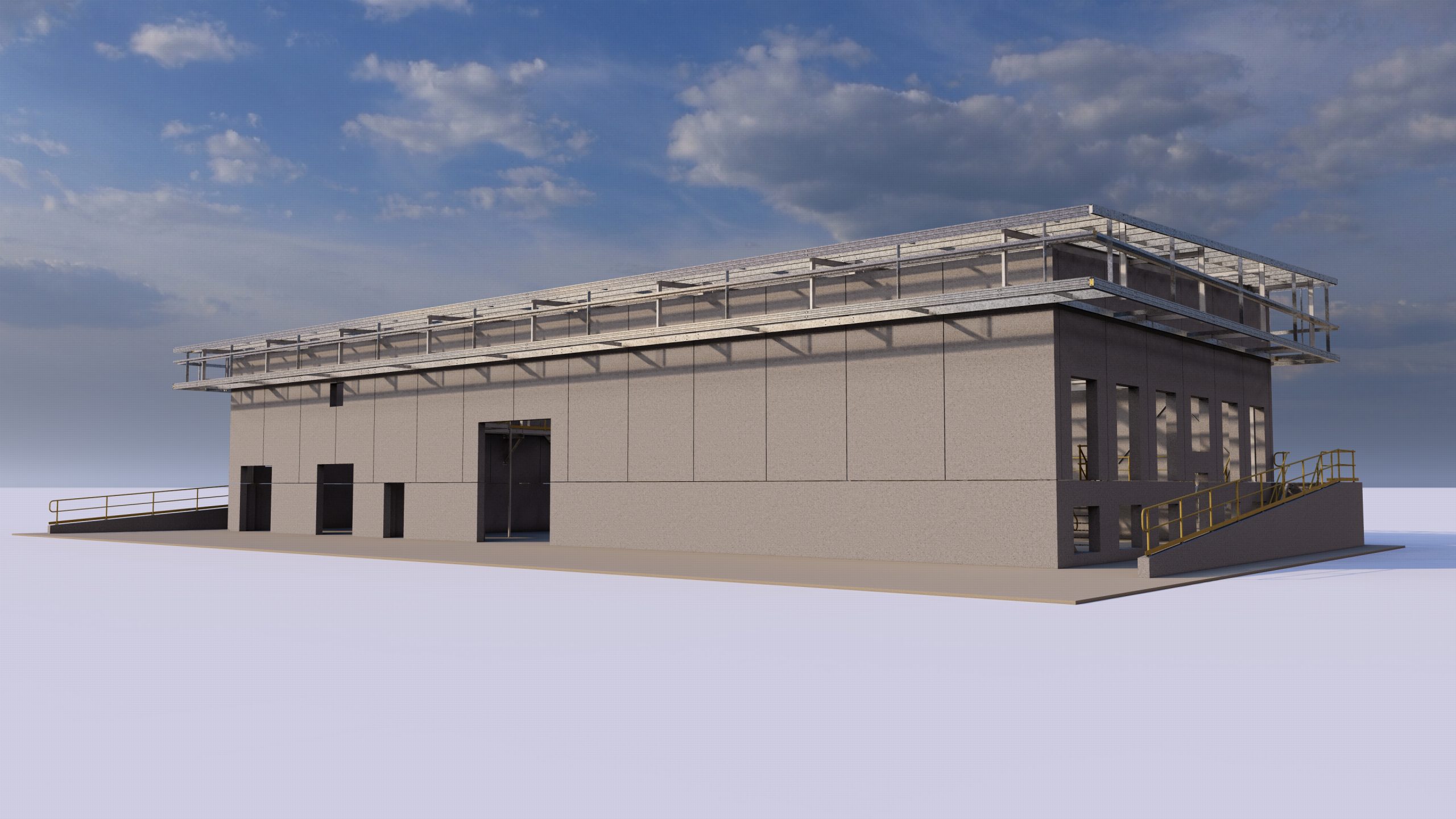

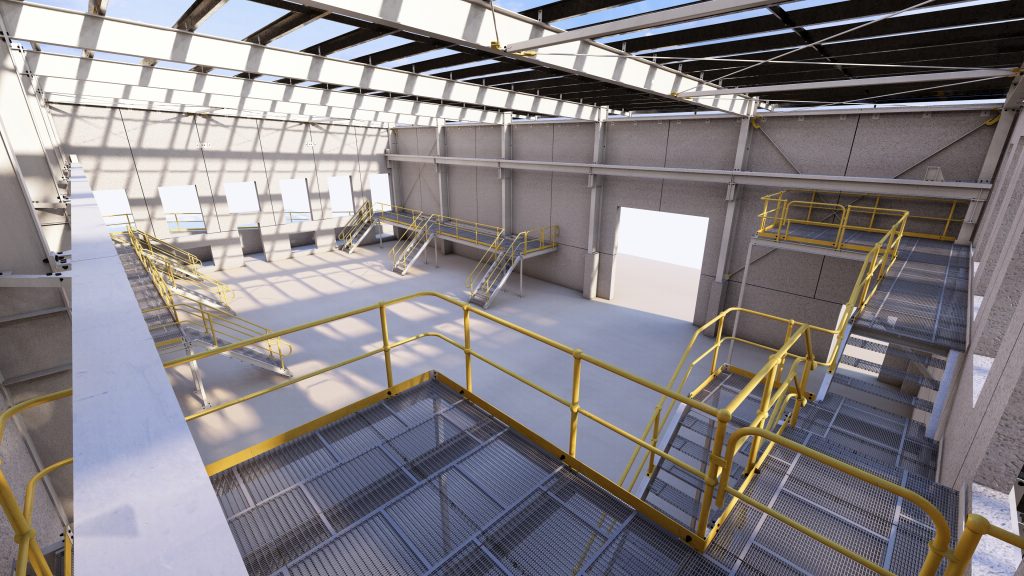

The main structure of the pumping station measures 39 metres in length and 17 metres in width, featuring eight robust steel portal frames that form the core of the building. Each frame was engineered for maximum efficiency and strength, with beams spanning up to 16 metres. These beams, built from UB 530×92.4 sections, ensure the stability required to support both the heavy mechanical systems inside and the environmental loads outside.

Beyond its dimensions, what truly defines this project is the attention to detail, from the early design stages to the on-site assembly.

Engineering Challenges and Solutions

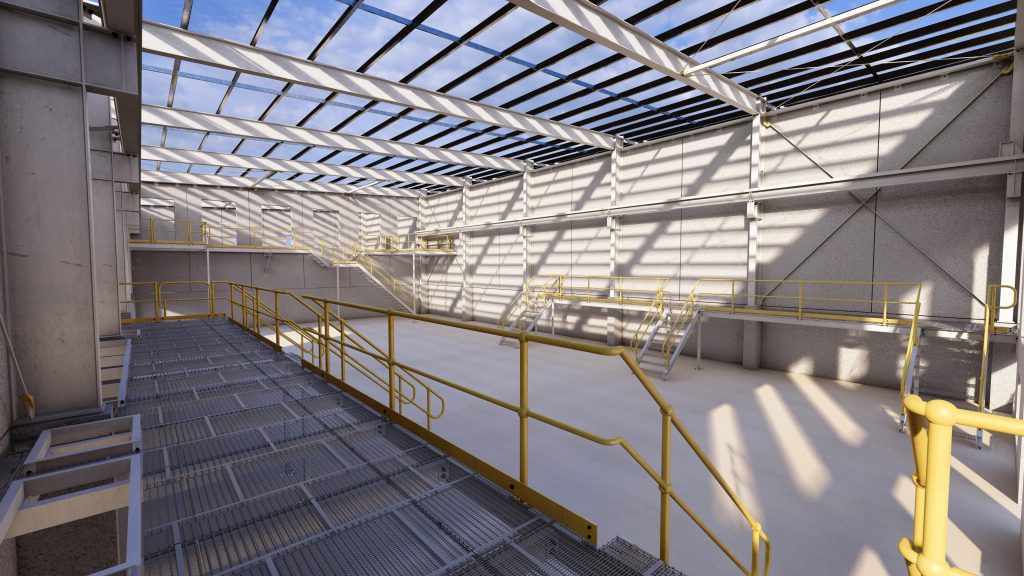

The Harrington Park Water Pumping Station demanded precise coordination between steel and concrete elements, resulting in a series of complex connections.

To achieve this, the design incorporated:

Every component was modelled in detail to avoid clashes and guarantee an efficient workflow, both in the fabrication shop and on-site.

From Model to Reality

A key part of the process was the use of submodels. Rather than handling the entire structure as one massive model, the design was strategically divided into smaller, manageable segments. Each submodel was carefully detailed, checked, and then sent to the workshop for fabrication.

This modular approach not only improved accuracy but also reduced on-site assembly time – ensuring each steel element fit perfectly into place during construction.

On-Site Execution

Once on site, the installation followed a tightly coordinated sequence. The portal frames were erected first to define the building envelope, followed by the mezzanine structures and crane rails. Careful alignment and surveying ensured every beam and connection met the required tolerances.

The result? A strong, functional, and precisely executed steel structure ready to support the critical operations of the water pumping station.

Why Precision Matters

Projects like Harrington Park highlight the importance of integrated steel design, where engineering, detailing, and fabrication are all connected through accurate digital modelling.

This approach reduces rework, minimizes errors, and leads to safer, faster, and more efficient construction.