Overview

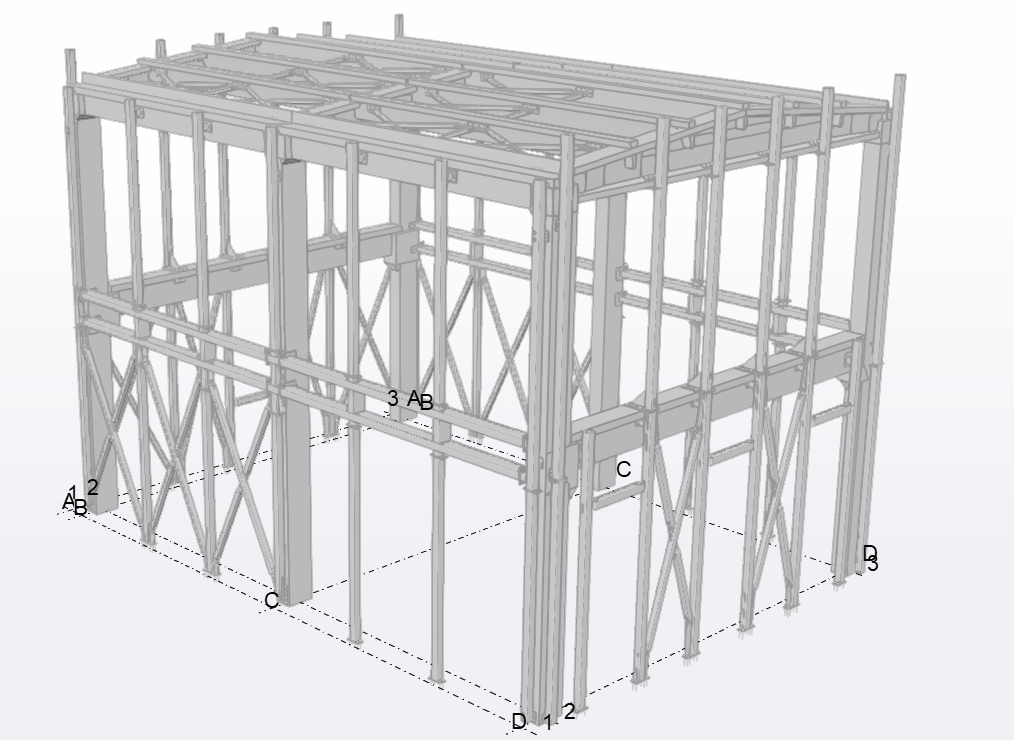

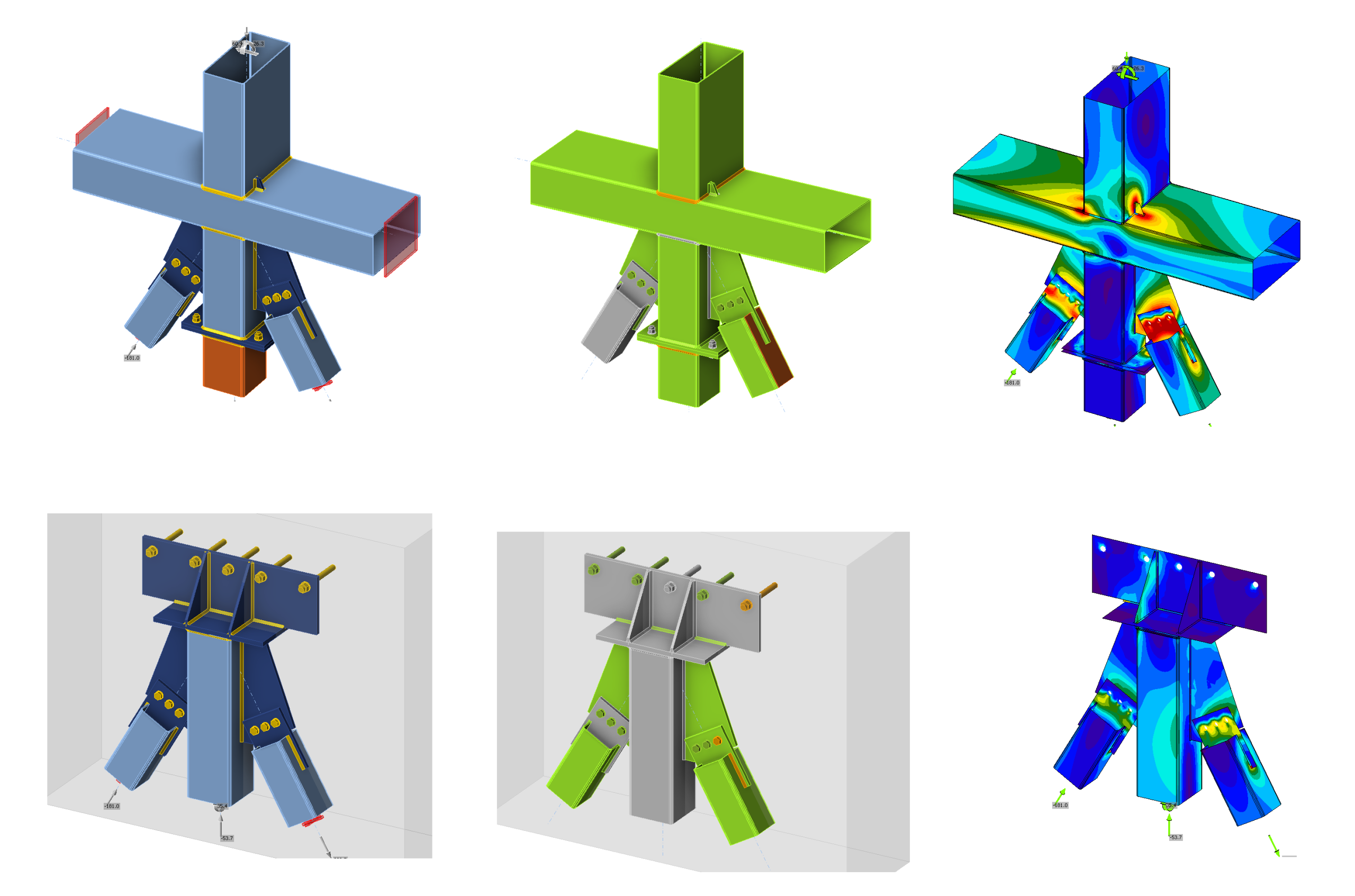

This project involved the detailed design of steel connections and fabrication models for a complex hybrid structure combining prefabricated concrete and structural steel. Our focus was on connection design and detailing, requiring close coordination with the global structural model due to the system’s hybrid nature.

Challenges

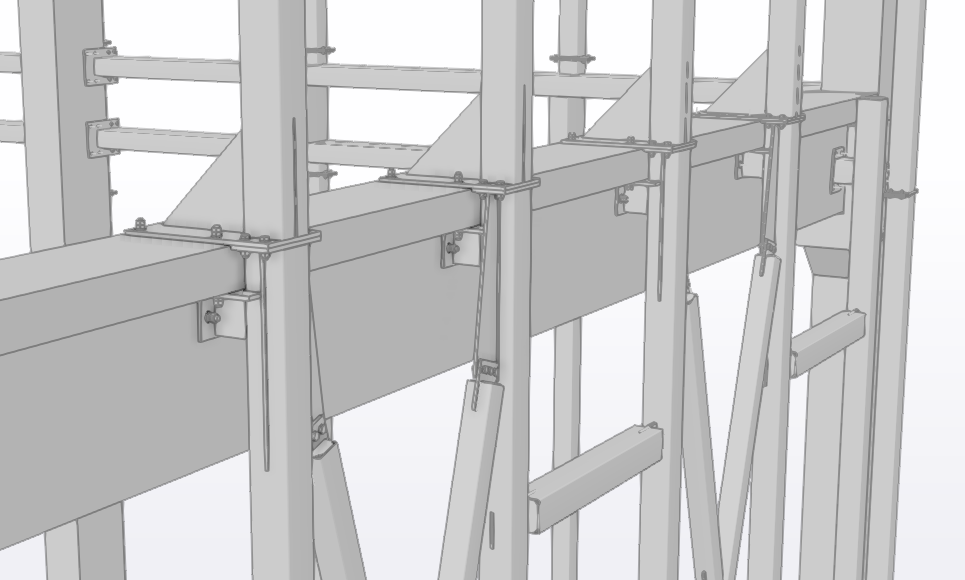

Integrating concrete and steel elements into a single system was the main challenge. The global analysis simplified the structure, but we needed to resolve the real-world connection details – especially where steel members on outer faces met precast T-beams centered on columns. These conditions demanded custom, compact, and constructible connections to ensure proper load transfer and performance.

Solutions

We developed bespoke connection designs supported by 3D modeling to coordinate geometry between the steel fabricator and precast supplier. This minimized tolerances and prevented clashes during installation.

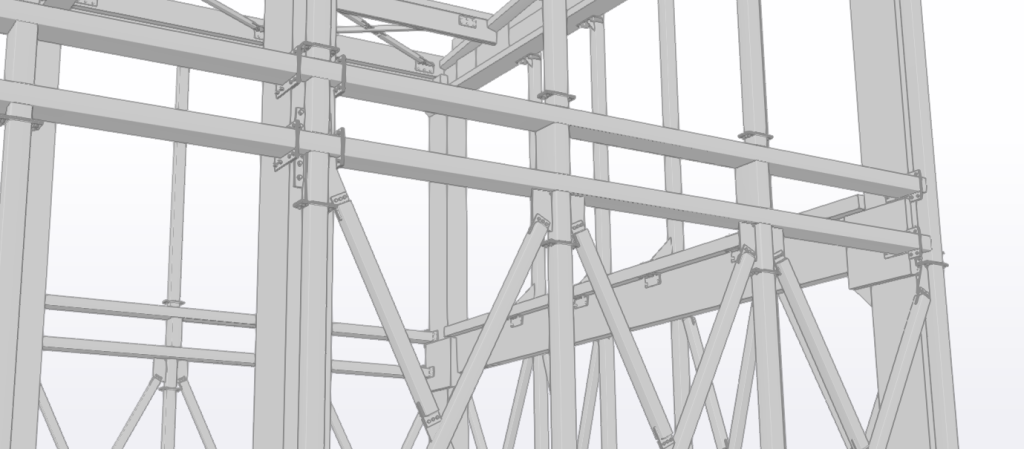

For the front canopy, we enhanced the global model to improve horizontal stiffness using a discrete bracing system, balancing stability with architectural lightness.

Results

The outcome was a coordinated fabrication model and detailed drawings that translated analytical concepts into buildable solutions. The hybrid system achieved both structural efficiency and visual coherence, while the redesigned canopy improved stability and constructability.