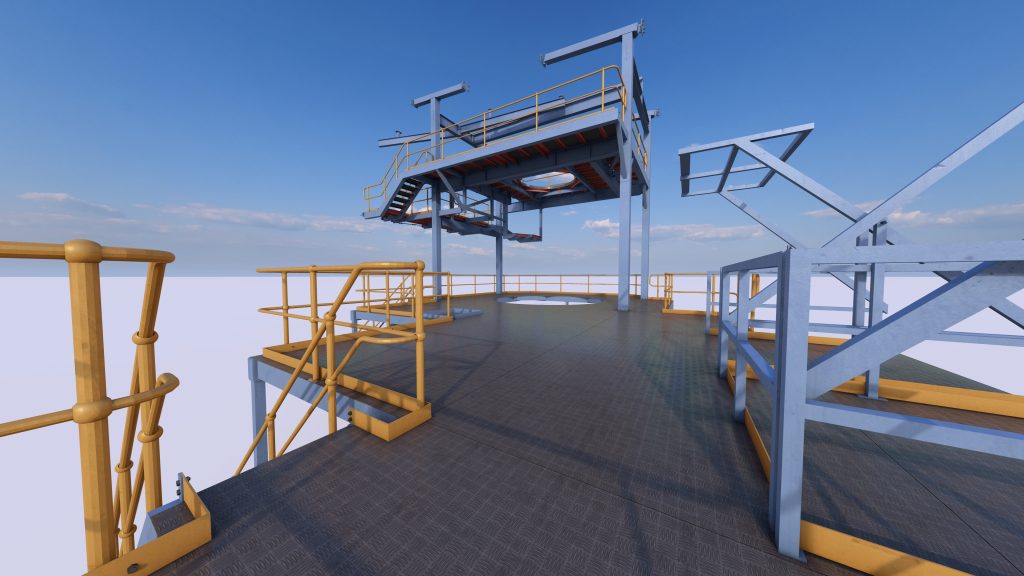

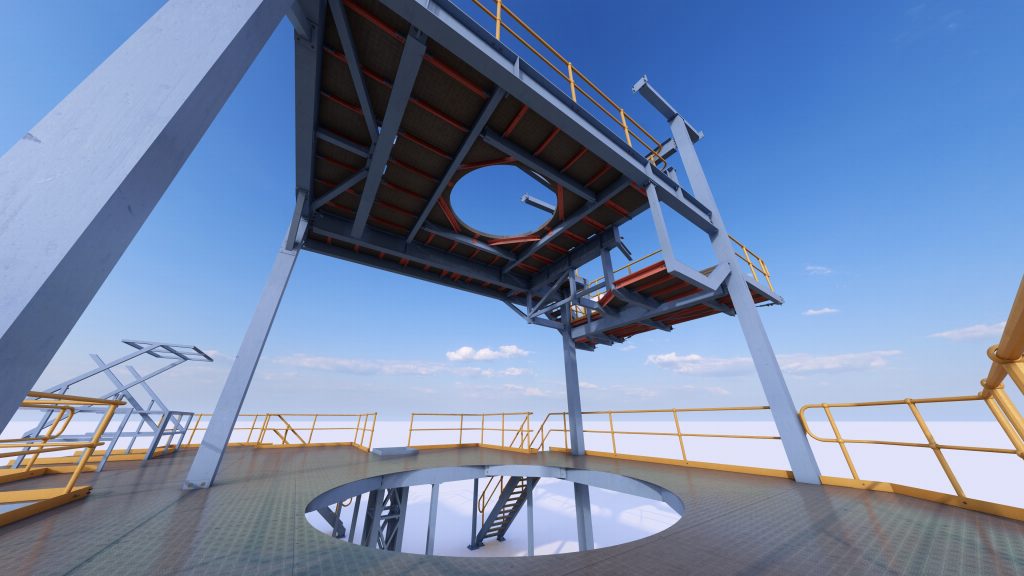

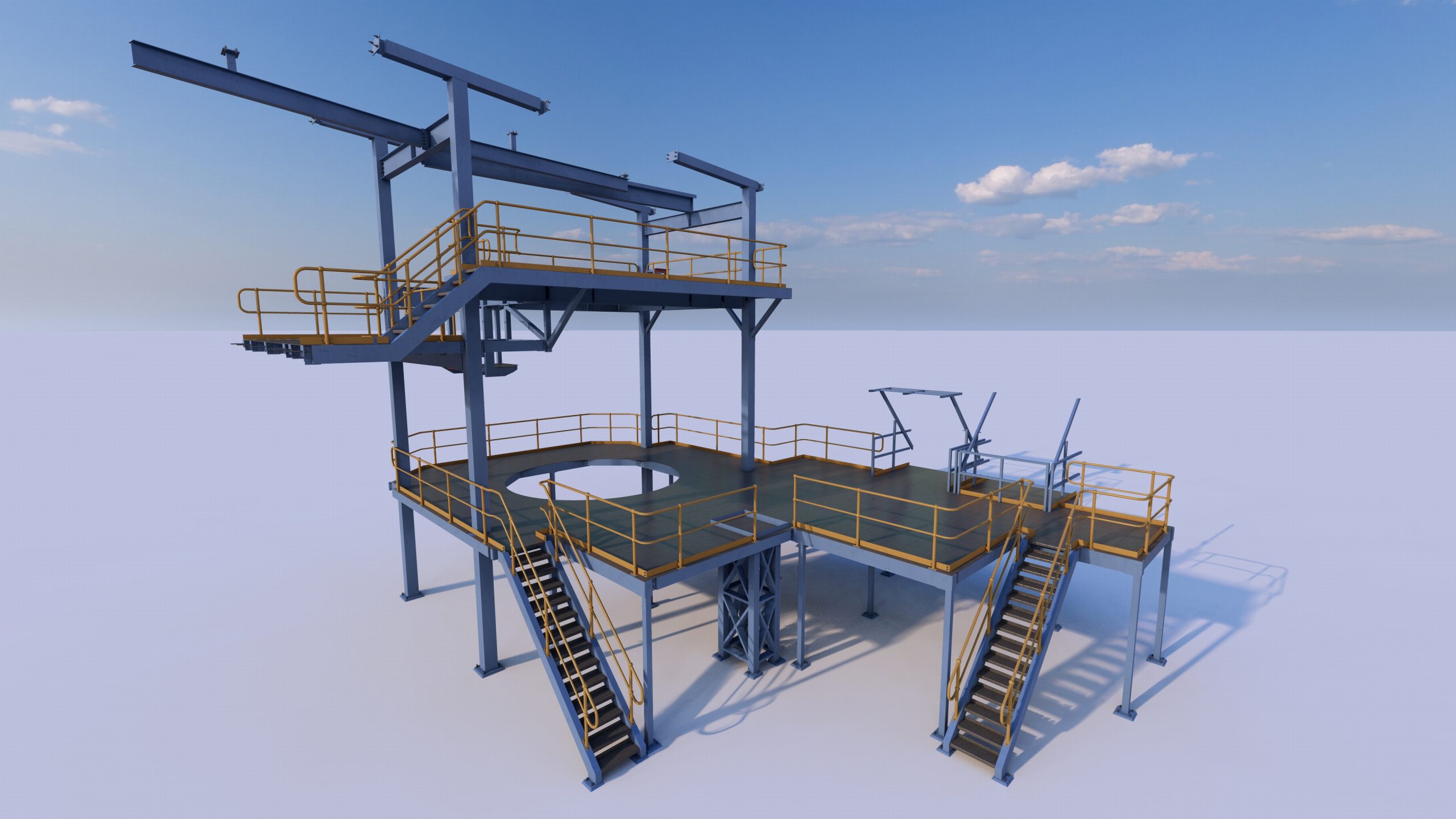

Building heavy steel structures inside an active food production facility presents a unique set of challenges – especially when hygiene is non-negotiable. That was the case with the Manildra Filler Platforms project, where we delivered a complete fabrication package under strict sanitary requirements.

The Scope

Our team was responsible for delivering the full scope:

All tasks were executed with the food industry’s demanding standards in mind – especially when it comes to cleanliness, durability, and efficiency.

The Challenge: Hygienic Design

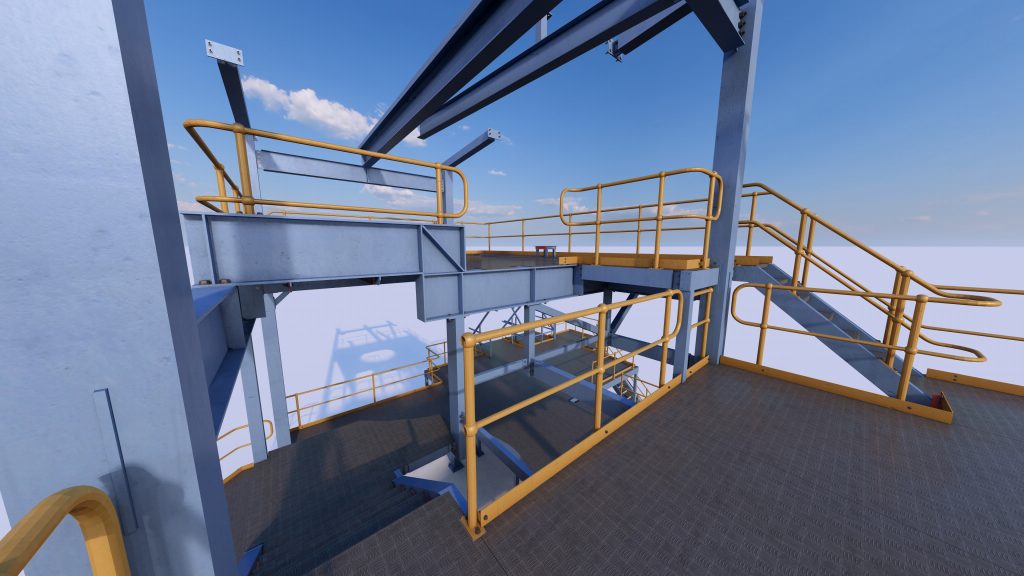

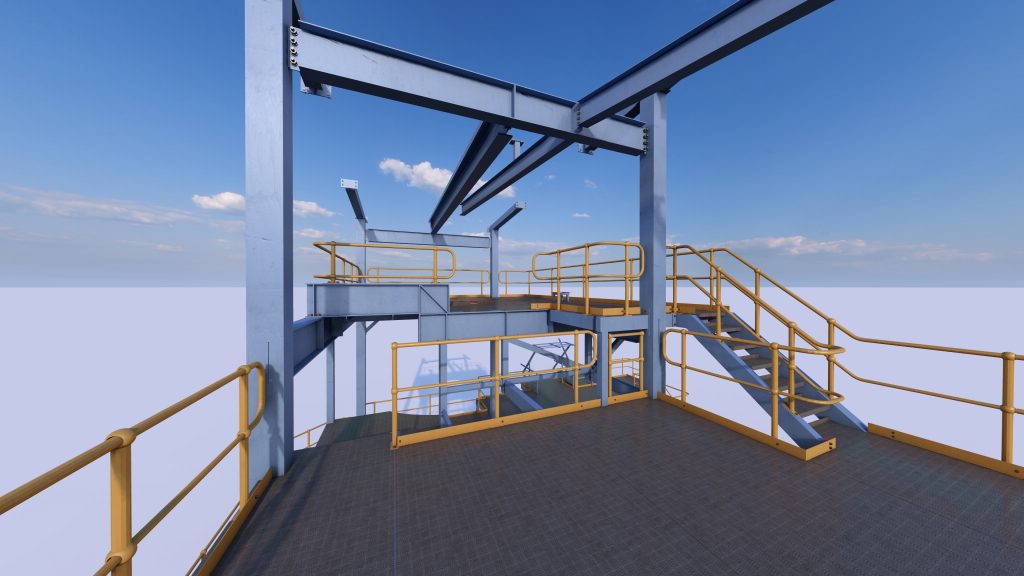

In food processing environments, designing for hygiene means eliminating every possible space where food particles or moisture could accumulate. That required not only technical precision but creative problem-solving from the earliest modeling stages.

The Solution

To ensure full compliance and long-term reliability, we implemented several key design strategies:

Collaborative Design Approach

From day one, we worked in close coordination with the client. The design was refined in parallel with the modeling process – an agile, collaborative approach that ensured every detail aligned with both hygiene standards and practical on-site needs.

The Result

The Manildra project stands as a great example of how thoughtful engineering, hygienic design, and efficient workflows can come together to solve complex challenges in live food production environments.

It’s not just about building structures – it’s about building the right structures, in the right way, for the right environment.